Silicone profiles and silicone foam profiles - made to order

Lindemann Silikon GmbH & Co.KG

Your Specialist in silicone

Contact nowSilicone profiles in any geometry

Our competence - silicone profiles and silicone sealing profiles

- the creation of technical drawings

- toolmaking

- the production of samples

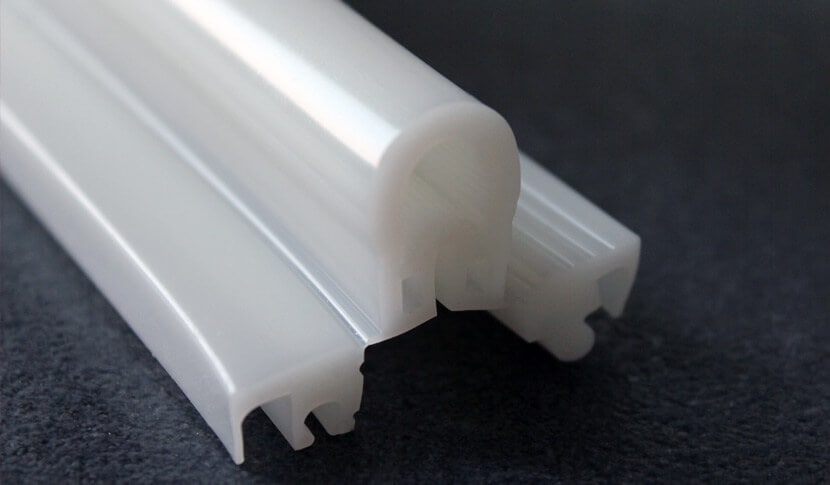

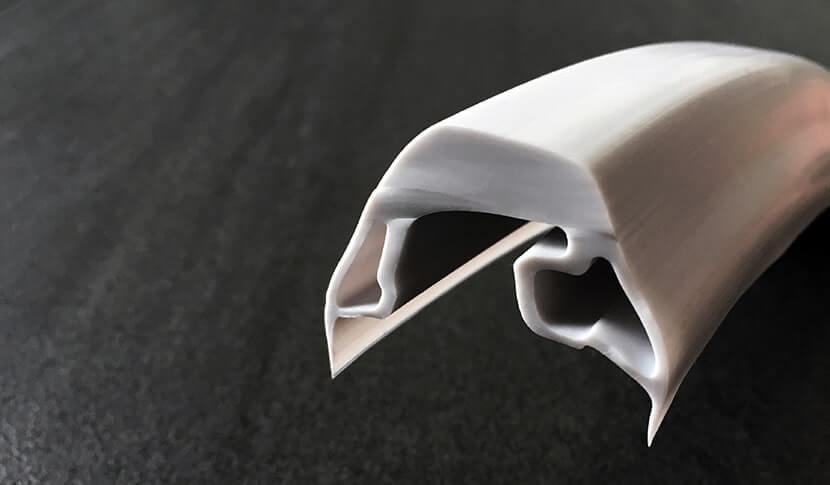

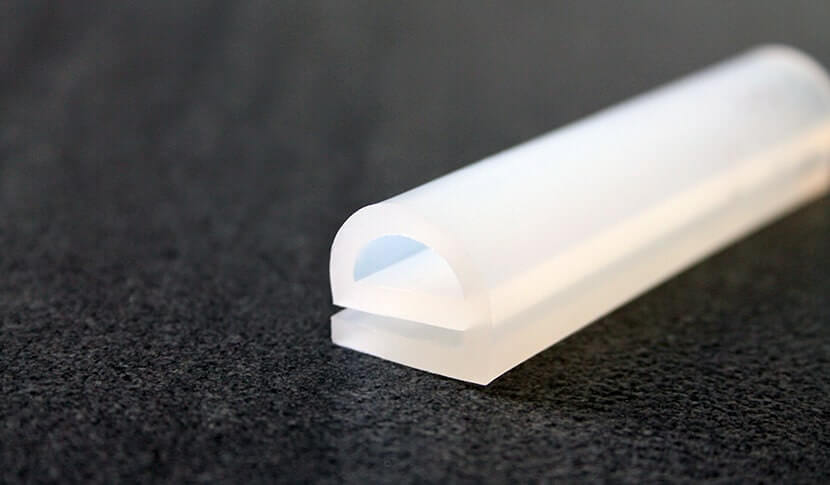

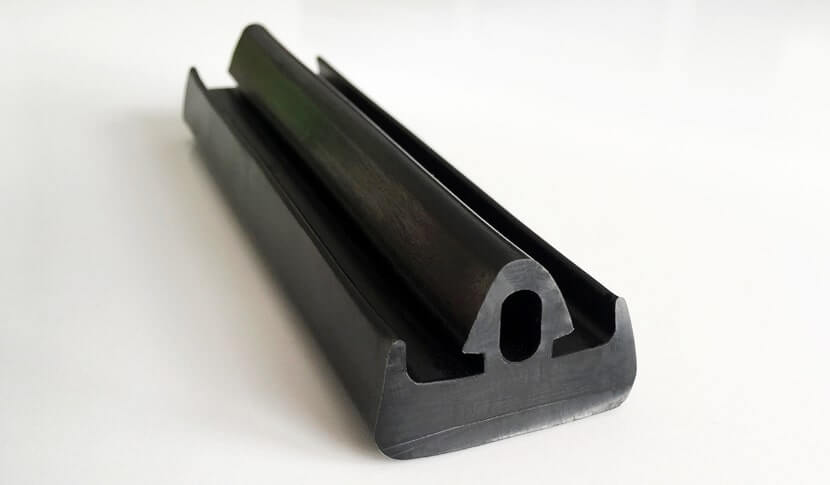

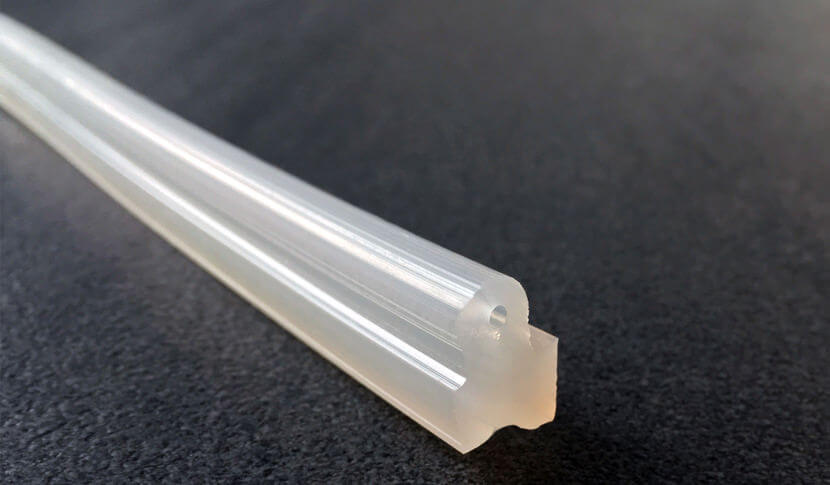

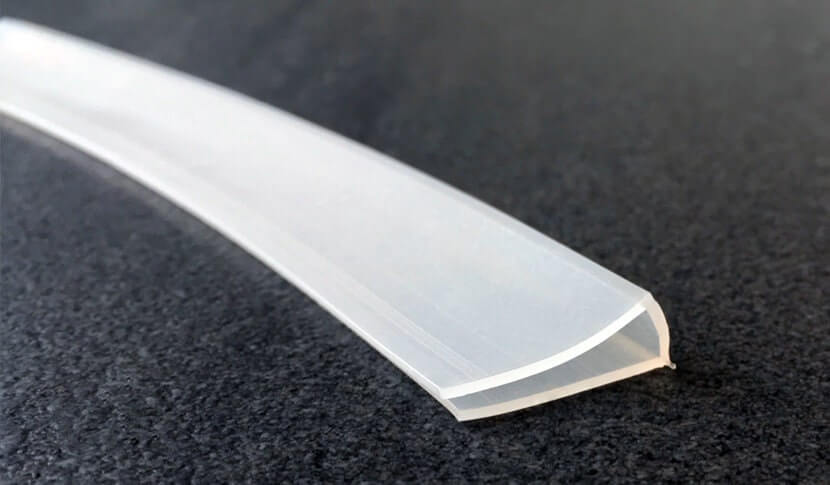

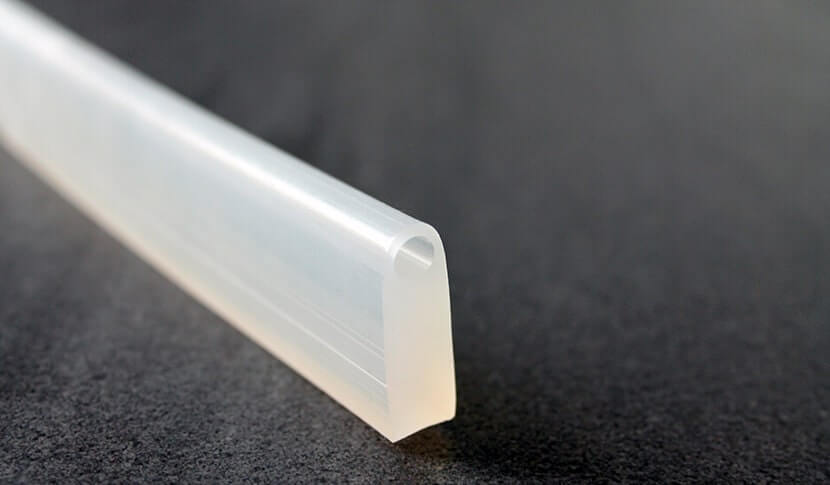

Our standard production program of silicone profiles includes various geometries.

Profile geometries without, as well as cross-sections with differently dimensioned hollow chambers can be produced:

- as foam or compact silicone

- with a Shore hardness between 15° and 90° Shore

- in any RAL colour

- platinum or peroxide crosslinked

- with any material in our range (tear-resistant, heat-stabilizing, self-extinguishing)

- with approval (food compliant, drinking water approved, etc.)

U-profiles, T-profiles and complex cross-sections are offered. It is also possible to make up profile rings or profile frames from extruded silicone profiles. In any case, precise planning of the geometries and careful production execution are very important. Each silicone profile is a custom-made product that can meet the highest quality standards. This applies regardless of whether the geometries are standard profiles, square profiles or more complex variants.

| Simple geometries Manufactureable external mass |

|

|---|---|

| Height in mm | width in mm |

| up to 60 mm | to 220 mm |

Simple geometries

Manufactureable external mass

Height in mm

up to 60mm

Width in mm

up to 220 mm

Silicone profiles that are to be used in the food or pharmaceutical industry must meet numerous requirements that are compatible with the legal regulations of the respective industry. Of course, all of this applies to the silicone profiles manufactured by J. Lindemann GmbH. Not only the geometries and the cross-section are important, but also the hardness. It can range from 15 to 90 Shore.

- biocompatible

- food safe

- Approved for drinking water

- odorless

- tasteless

- ozone resistant

- weatherproof

- aging resistant and

- temperature resistant.

The latter can be particularly emphasized, because the silicone profiles are able to tolerate temperatures between -100 degrees Celsius and 300 degrees Celsius without damage. You have the opportunity to choose the color of the profiles themselves. There are no restrictions. The series size is a minimum of 25 meters, with no upper limits.

| Properties Profiles | |

|---|---|

| Hardness | 15° to 90° Shore |

| Colour | Any RAL colour and colour setting according to customer specifications |

| Temperature resistance | -100°C to +300°C |

| Tear resistance | 16 kN/m to 45 kN/m |

| Elongation at break | 200% to 1000% |

Properties Profiles

Hardness

Color

Temperature

Further tear resistance

Elongation

15° to 90° Shore

Each RAL colour and colour setting according to customer specifications

-100°C to +300°C

16 kN/m to 45 kN/m

200% to 1,000%

Silicone foam profiles

- Significantly lower density

- higher compression

- higher reset behaviour

The foam profiles can be produced in any geometry:

- Standard geometry as square profile

- Complex geometries

Depending on the dosage of the propellant, different foam types are possible.

| Profile foam properties | |

|---|---|

| Shore Hardness A | Density g/cm3 |

| 5° to 30° | 0.25 to 0.65 |

Profile foam properties

Shore Hardness A

5° to 30°

Density g/cm3

0.25 to 0.65

With regard to the physiological properties of silicone foam, there are two mixtures:

- Technical, NON-FDA Quality

- FDA Quality

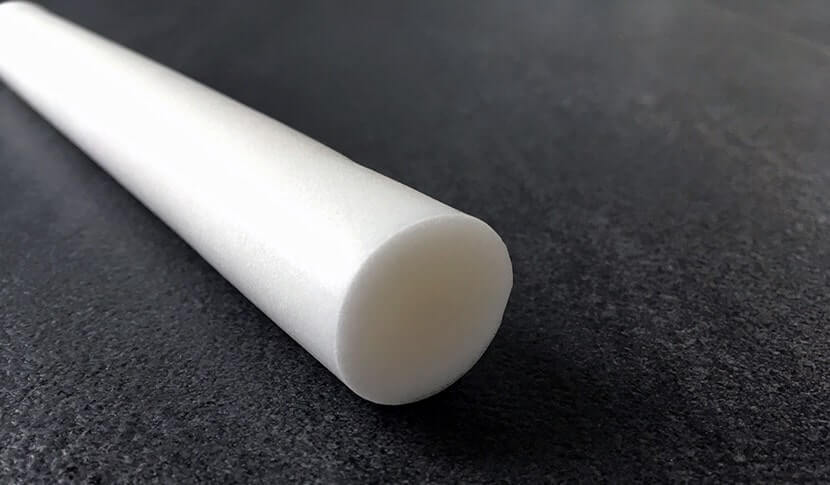

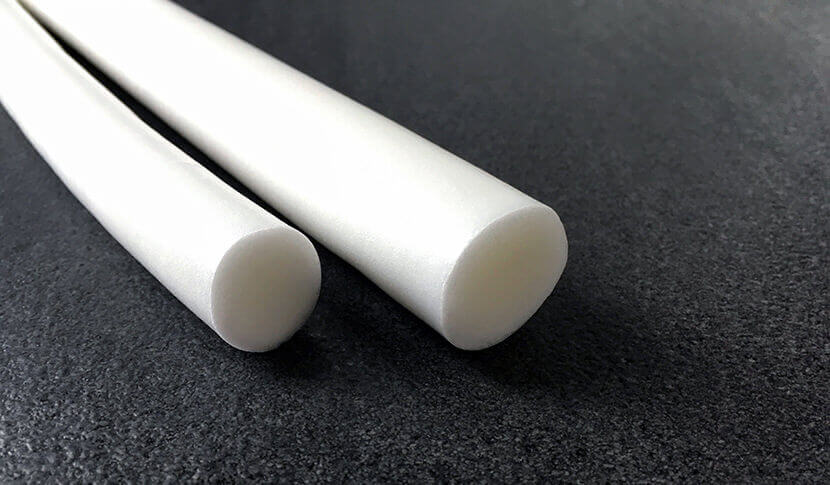

Silicone round cords - Foam profiles - Foam round cords

The company J. Lindemann offers silicone round cords with diameters between 1 mm and 50 mm. The same applies to foam round cords.

Various approvals are available for our round cords on the base compounds.

Foam round cords

Similar to the hoses, round cords can be foamed with special propellants.

The foam round cords can be manufactured in the same dimensions as a compact cord.

Depending on the dosage of the propellant, different foam types are possible, with different Shore and density types.

With regard to the physiological properties of silicone foam, there are two mixtures:

- Technical, NON-FDA Quality

- FDA Quality

There are numerous options in this area. At the customer’s request, the profiles can be glued to form rings or frames. In addition, self-adhesive profiles can be applied or surface treatments can be carried out. Contact us, we will find an individual solution.

Various approvals are possible for our profiles, round cords and foam round cords on the basic compounds.

All quality standards and norms of this industry must be met. This applies regardless of whether the silicone profiles are to be used for end applications in the bakery and restaurant or in systems and machines for the production of food.

- BfR XV Silicone

- FDA section 177,2600

- EC VNr. 1935/2004

- KTW A hot and cold water

- DVGW W 270

- WRAS

- 3 A Sanitary Standard

Special requirements apply in the pharmaceutical industry. For example, the profiles must not only be biocompatible, but also:

- sterilizable

- long lasting and

- chemically resistant to cleaning agents and disinfectants.

Furthermore, you must comply with the legal regulations that apply in the pharmaceutical industry:

- USP Class VI

- ISO 10993

- Tool making for demanding profiles

- Rapid Prototyping

- any cross-section can be produced, in any hardness and colour

- foamed profiles

- self-adhesive profiles

Are you interested in our products or a question? Then contact us now.